Chemical

Persistent Organic Pollutants and Emerged/Emerging contaminants

A trendy area of research, but driven in part by the Water Framework Directive and a significant problem for regulators but as discussed by Sauvé et al in ‘A review of what is an emerging contaminant’ are we considering:

- emerging contaminants (contaminants which have appeared only recently);

- contaminants of emerging concerns (contaminants which have been in the environment for a while but for which concerns have been raised much more recently); or

- emerging issues related to more traditional contaminants.

In some ways in terms of laboratory developments it is all of the above with the need to develop new analytical methods, equipment/systems to make tests more commercially viable and/or lower detection limits (The Government Chemist undertook a review of measurement techniques for measuring priority substances in 2015 the results of which can be found here). However, in terms of regulating water quality definitions matter. Since much of our groundwater policy is derived from Europe, the EC supported NORMAN Network which defines emerging pollutants as pollutants that are currently not included in routine monitoring programmes at the European level and which may be candidates for future regulation, depending on research on:

- their (eco)toxicity;

- potential health effects and public perception;

- monitoring data regarding their occurrence.

These emerging contaminants of concern are primarily Persistent Organic Pollutants (POPs) - a group of organic compounds of concern in the environment due to their persistence, toxicity, and bioaccumulative properties (PBTs), with a high potential to significantly affect human health. They cover a range of chemistries, but are often grouped into pesticides, herbicides, industrial by-products and health care products. Where POPs have emerged they form part of the EU’s regulation on persistent organic pollutants (recast June 2019) and are referenced in several legislative documents such as the Water Framework Directive (WFD), the Groundwater Directive, the Industrial Emissions Directive and the Waste Directive (WM3).

There are currently 45 compounds on the Priority Substance (PS) list (Annex 1 Directive 2013/39/EU), although this includes three metals (mercury, cadmium and lead), and a Watch List exists whereby additional compounds may be added, once sufficient data is available. The toxic concentration of these organic compounds is often very low, and therefore detection limits need to be correspondingly lower. The instrumentation now implemented utilises a combination of Gas Chromatography -Mass Spectrometry (GCMS) and LCMS, capable of reaching lower detection limits.

- GCMS Target Based Screening – full scan mode using Deconvolution Reporting Software (DRS) to identify over 1000 compounds, including all compounds in the WFD.

- LCMS Triple Quad – validated for acid herbicides down to ppt levels.

- GCMS Triple Quad – validated for key pesticides, including chlorinated and phosphorylated pesticides, plus triazine, again down to ppt levels.

The Watch List committee collates monitoring data from several European countries to determine if a potentially toxic compound is appearing often enough to be added to the list. Currently, the focus is on selected pharmaceutical products, hormonal compounds, microsilicones and microplastics.

In addition to new compounds of concern, substances which have been on the list for some years will be revisited, due to new information regarding toxicity levels, and a new acceptable limit may be set. For example, seven of the 33 priority substances listed in the 2008 EU Priority Substances Directive changed in 2013 with some significant reductions in acceptable limits such as the annual average threshold for Fluoranthene going from 0.1ug/l to 0.0063ug/l and for benzo(a)pyrene going from 0.05ug/l to 0.00017ug/l.

Benefits of newly developed GC x GC Techniques

In a commercial world it is not just reaching these lower limits of detection that is of concern but the demand for ever faster turn arounds. The development of two dimensional gas chromatography (GCxGC) can give clients speciated extractable petroleum hydrocarbons (EPH) data on turnarounds up to 50% faster than traditional methods. Speciated EPH methods give the end user analytical data that allows them to characterise and classify hydrocarbon impacted sites and assign appropriate remediation strategies. Any improvement in the turnaround speed of results has a direct impact on their costs, especially when expensive earthworks are involved.

Traditional speciated EPH methods are based around solid phase extraction (SPE); SPE is a technique which separates solvent extracts into Aliphatic (straight chain) compounds and Aromatic (cyclic/ringed) compounds for analysis. SPE is a challenging, time consuming process which produces two sample extracts for analysis by GC.

The SPE process requires close supervision by experienced analysts to minimise potential errors. One of the most common issues is with Aliphatic breakthrough into the Aromatic fraction, this can cause elevated reporting in Aromatic bands which has significant consequences for site risk assessment and subsequent remediation costs. The GCxGC EPH method which gives speciated Aliphatic and Aromatic banded data from a single solvent extract without the need for SPE. The GCxGC EPH method gives a significant turnaround time advantage over traditional methods in both sample preparation and analysis.

Conventional one dimensional chromatography typically involves 3 steps:

- Sample injection/volatilisation

- Column separation

- Detection (FID, MS, ECD…)

GCxGC introduces a modulation step and a second dimension column separation:

- Sample injection/volatilisation

- Column separation

- Modulation

- Column separation

- Detection (FID, MS, ECD…)

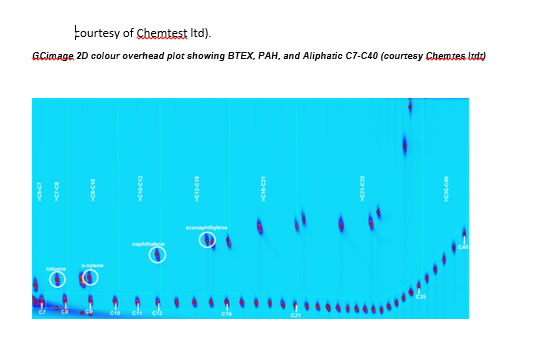

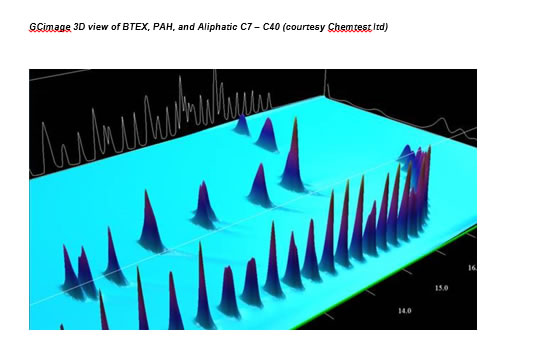

The data collected from the detection method can be used to produce 2D colour/contour plot and a 3D visualisation of the data using GC image software ( as can be seen below courtesy of Chemtest ltd).

The use of GCxGC technology has evolved the analysis of speciated EPH, and is not just a ‘like for like’ replacement for SPE based methods. There are genuine advantages over the older technique(s):

- Turnaround times are reduced.

- Reduction in solvent use has cost, health and safety, and environmental benefits.

- Simplification of the preparation procedure improves method precision and bias.

- Chromatographic separation of Aliphatic and Aromatic compounds is more reliable and reproducible than SPE.

Asbestos in soils respirable fibres in respirable dust

In recent years, the testing of soil for asbestos has become commonplace, often for purposes of risk assessment on brownfield sites. The most common analysis for this purpose is presence and identification of asbestos, followed by quantification of the percentage mass of asbestos in the soil.

The problem with this approach is that percentage mass of asbestos in soil does not directly relate to the risk posed of fibres being released and inhaled, the primary exposure pathway. As a simple example, 0.1% asbestos bound within an ACM, such as asbestos cement, presents a much lower immediate risk than 0.1 % of free fibres within the soil, as the risk to human health comes from airborne, respirable fibres.

Dust monitoring focuses on PM10 concentrations - the amount of particles with diameters of less than 10µm. Therefore, a more useful test would be to calculate the possible asbestos concentration in this fraction of the sample, in terms of fibres per mg (f/mg PM10) and effectively to perform a test equivalent to the asbestos air test on the respirable portion of the soil. The test is performed by collecting a sample of PM10 material onto a filter and performing a fibre count, using the same fibre counting rules as specified in HSG248 for asbestos air testing. This means that it is now possible to provide an estimate of three key indicators of risk that could not be calculated just by measuring the mass percent of asbestos:

- The fibres per ml of asbestos in air at a given level of dustiness (for example, 0.5 mg m3 – the OEL for dust)

- The dustiness level on site that would need to be reached before the clearance indicator of 0.01 f/ml would be breached

- The dustiness level on site that would need to be reached before the control limit of 0.1 f/ml would be breached

Advantages of the method

- The results provide a good indication of whether site activities are likely to give rise to airborne fibres, and to what levels

- The results allow a decision to be made about the level of air monitoring that will be required, based on the requirements of the Control of Asbestos Regulations

- The results allow informed decisions about dust suppression to be made

- By removing factors that affect the release of fibres from soil, such as soil type, particle size and moisture content, the risk can be assessed more accurately

- Once a result has been calculated for the likely fibre content of the respirable dust, the on-site measurements could then focus on the levels of dust being generated on-site, which is much cheaper than asbestos air testing.

- Cost – The test is significantly less expensive than the fibre release test, and can be scheduled as well as, or instead of, quantification. Also, no additional equipment, and only minimal additional training would be required for laboratories already performing quantitative analysis.